PLD IRRADIATION TEST PROJECT

The aim of this project is to develop a circuit board in order to test

a candidate programmable logic device (PLD) for implementing a radiation

tolerant S-LINK source card

(LSC). This board can be used as a simplex S-LINK Link Source Card that

is using G-LINK as physical layer, or as a data generator test card for

radiation testing. The actual function depends on the configuration

of the FPGA.

If the FPGA is configured for data generator, two independent data paths

can be used to check the correct functioning of the card. At this configuration

the card requires three control signals on its differential (RS-422) inputs

which select test patterns or reset the card. Four different data

patterns can be selected by the control signals. The FPGA generates

"Test Pulses" on four differential lines, which monitor the internal functioning

of the digital logic. These four signals are transmitted to a data analyzer

via an RS-422 Line Driver and twisted pair cable connections.

The second data path serves for monitoring the joint functioning of

the FPGA, Serializer and Media Interface. Test pattern generated

by the FPGA is framed into 224+2 word packets which start and terminate

with a control word. The four MSB of the data words contain parity bits

for each four bits respectively. The serialized data is transmitted

using optical (any standard 9 pin) or electrical (Lemo connector) media

interface.

In case the FPGA is configured for S-Link Source, the card serializes

and transmits the data which is sent to its S-LINK connector via electrical

or optical media . The simplex G-LINK

LDC can be used as receiver.

Single Event Effect and Total Dose tests will investigate the adequacy

of the selected devices for the ATLAS

Front-End links. Expected error rate will be established for the different

Front-End link environments.

Radiation Test Setup

FPGA Design Block Diagram

Different test patterns can be generated by the loadable circular shift

registers (walking 1, walking 0, alternating bits, walking FF). This data

is sent to the G-Link serializer. To test the internal functioning of the

PLD, four shift registers are implemented, two with triple modular redundancy

which reduces the single event upset probablity and two using single flip-flops.

One data path is sent to and fed-back from device pins to test the I/O

circuits as well. The data patterns at the outputs of the shift registers

are compared in each clock cycle. If no errors have occurred, the comparison

result will be true. If a SEU (Single Event Upset) occurs in one

of the shift registers, in the I/O feedback path or in the comparator,

the result of the comparison will be false. Since the signaling speed is

limited on the twisted pairs going to the control room, multiple words

are compared in one "test period" and a latch will be toggled if one or

more comparison errors occur during this time. The length of a test period

is 6.4us. At the end of each test period a "control pulse" is sent from

a counter on one twisted pair. Similar, "test" pulses are generated on

the 3 other twisted pairs in case no comparison errors occurred during

the test period. The theoretical error probability (the probability that

the pulse is missing at the end of a test period) is different on each

line. The shift registers are reloaded at the beginning of each test period.

This method ensures a slow signaling rate on the twisted pairs and full

speed operation of the internal logic circuits. All logic circuits are

synchronous, the clock frequency is 40Mhz which is the read-out frequency

of most ATLAS Front-End links. SEU mitigation methods should be used to

implement the control pulse generating circuits.

Test pulses are sent to the control room

A Line Receiver will send the received pulses to a PC via a National

Instruments PCI-DIO-32-HS high speed digital I/O module. Data acquisition

and error detection is controlled from Labview. The error detection can

detect if one or more (control or test) pulse is missing or if non of the

pulses are received, as control pulses will arrive periodically. If the

control pulse is missing, it is due to an error occured in the pulse generator

circuit. In case no pulses are received for a longer period, permanent

damage of the circuit is probable. In this case manual intervention (system

reset or power down) is necessary.

(Re)Started with pattern 1010101010 06/04/08:38:46

23295.88 3

(Re)Started with pattern 1010101010 07/04/08:39:47

(Re)Started with pattern 1010101010 07/04/08:45:47

(Re)Started with pattern Walking One 07/04/08:47:16

15490.25 3

15633.71 C

19069.58 C

3

44502.39 3

56896.82 E

59727.74 8

7

60010.22 8

|

Example of an error log file generated with Labview:

Test pattern, Start time, Error type and Time stamps in seconds

relative to start time are recorded

The G-LINK serialiser (HDMP-1022) sends serial data to the optical media

interface. At the receiving side the simplex G-LINK

LDC will be used. The FPGA of this card includes an automatic data

checker, so this card will check the data pattern, parity and packet length

of the received packets. In case of mismatch, an error code is generated

and the erroneous data with the error code will be written into the host

computer (PC, Linux).

The LDC checks the received data and sends the error code (TEST

tag on the picture) to the Logic Analyzer

On this picture the analyzer triggered on a Parity and Data comparison

Error

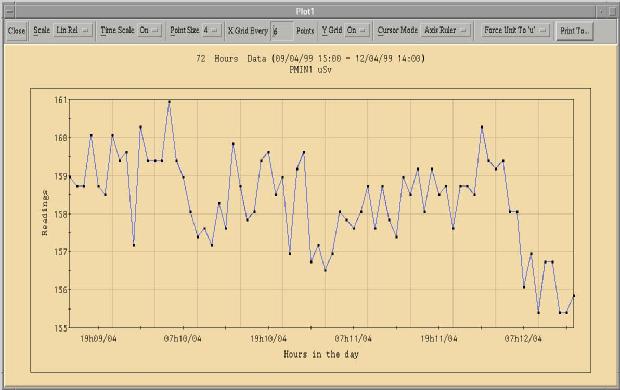

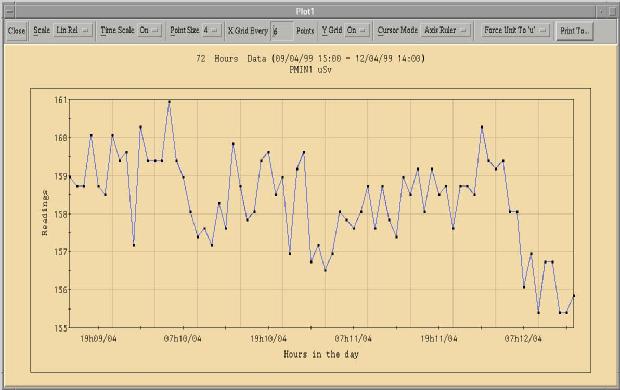

Radiation Environment

TCC2

This card will be first irradiated in the TCC2

area of the SPS accelerator. The estimated dose rate is about 50 Gy

and 5.1010 neutrons/cm-2 which can be accumulated in a 6 week running period

of SPS. In one year depending on how the accelerators are operating,

this gives 3x10**11 neutrons cm-2. The dose rate is monitored on-line at

7

locations of the test-area. The card is mounted on a SLITEST board

and inserted into a VME crate close to PMITC03 and PMITC04 dosimeters.

Dose measurements can be found here.

The TTC2 area, looking along the beams

On-Line Radiation Monitor Display

PSI

We irradiated the FPGA on this card at Paul

Scherrer Institute, in a focused proton

beam which is originally used for medical purpose. This beam is a ~64

MeV proton beam at 1.25E9 p/cm^2/s. It corresponds to an 0.5 MRad /h dose

rate or 1E13 n/cm^2/h (1MeV) neutron fluence.

Circuit Board Description

The board is powered through the S-Link connector. The ACTEL

A54SX16 FPGA generates test data for G-Link, and test signals for monitoring

the FPGA only. G-Link data is serialised by the HDMP-1022 G-Link transmitter

chip. Serial data is sent to the Methode

19-4-1-S (Multimode, 850nm) laser driver. The FPGA-test signals from

the FPGA are sent to the HS-26C31RH radiation

hard Line Driver which transmits the data to the control room via 4

twisted pairs. The HS-26C32RH radiation

hard Line Receiver receives control signals (reset, pattern select)

from the control room. A TEMEC

QEN47CHRAY100SB 40 Mhz quartz oscillator is used as system clock

source, the 3.3V FPGA is powered by a LM117H

linear regulator.

All signals of the S-Link connector are connected to I/O pins of the

Actel chip so with a proper FPGA configuration this board can be used as

a G-LINK based S-Link source card, which can transmit 16 or 32 bit words

at max. 150 Mbyte/s.

G-Link - S-Link Source Card for Radiation Tests

Main Components

FPGA: ACTEL A54SX16

Quartz Oscillator: TEMEX

QEN series (or VECTRON

M55310 series)

Voltage Regulator: (for 5V -> 3.3V conversion) LM117HTotal

Dose Test Results SEL

test results

As this chip did not fulfil our requirements, we are planning

to test the HS-117RH

regulator.

Serializer: HDMP

- 1022 (HP - G-Link Transmitter) Radiation

Testing Results

Media interface: Methode MDX-19-4-1-S Radiation

Testing Results

RS-422 Line Driver/Receiver: HS-26C31RH

/ HS-26C32RH

Power Filtering Capacitors: 470nF, ceramic

Results (Preliminary)

-

On the first two weeks the card was powered from the power supply of a

VME Crate. A power MOSFET transistor was found to be extreamly sensitive

to radiation in the VME's power supply and three power supply units have

died in a very short period, after a few Grays of radiation.

-

The power supply was changed to an external one which is placed to an area

where the dose rate is relatively low.

-

The total accumuted dose between 5th of April and 7th of June is ~ 5Krad.

The card stopped functioning on the 7th of July at 21:21. The problem was

the degradation of the LM117H

Linear Regulator chip which generates 3.3V supply voltage from 5V for the

Actel chip. Its output voltage has dropped to 25% of its before irradiation

value. The chip was replaced on the 29th. of July.

-

Both bit upsets and synchronisation errors were observed on the datalink.

As the FPGA did not have any SEUs these errors were caused by the serialiser

or the laser driver. The upset rate was in correlation with the changing

dose rate. The most errors were measured on the 3rd. of July: 160 bit flips

and 21 loss of synchronisation. The average error rate between the 3rd

of June and the 7th of July is 10-20 bit flips and 1-4 synchronisation

errors per day.

-

No errors were observed on the A54SX16 FPGA.

-

The Actel chip also survived a 90 minutes irradiation period at PSI

(750Krad!) and no single events were observed. These results are to be

verified as this chip did not survive so high total dose at NASA-GSFC.->

-

The Actel chip (An A54SX16 from the same order) was irradiated by Rich

Katz at NASA-GSFC with a Co-60 source, the dose rate was appr. 1 krad(Si)/hour.

TEST

RESULTS

Number of detected Single Event Upsets from 3/6 to 7/7 1999

Future plans to make

a radiation hard Gigabit datlink card

As technology advances the supply voltage of the digital chips is decreasing.

At the design of this board we could not avoid using circuits with different

supply voltages (5V and 3.3V) on the same board, generating the lower supply

voltage with a voltage regulator. As 2.5 supply voltage chips will also

appear in the future we probable will be able to eliminate the use of a

voltage regulator. The present LM117H

chip proved to be rather sensitive to radiation. We are planning to radiation

test the HS-117RH

radiation hardened voltage regulator.

It is necessary to find a radiation tolerand serialiser which does not

loose synchronisation in radiation since thousands of datawords are lost

while the link regains synchronisation.

Future investigations are necessary to prove the radiation tolerance

of the Media Interface.

Last updated: 25.11.1999

Any comments, questions and critics are welcome!

Zoltán

Meggyesi

CERN / KFKI-RMKI